Expansion joints to absorb movements in pipes

Expansion joints are used to absorb movements in a pipe, so that the movement stops in the compensator and thus prevents damage to other equipment. The correct compensator must be selected in accordance with what stresses it is exposed to and what type of movement it must absorb. We distinguish the movements mainly as:

Axial movements

Comes from stretching or pushing, which can e.g. a. come from expansion or compression during large temperature changes.

Angle movements / Angular movement

Comes from the pipe being bent, and can e.g. a. is caused by two pipes that meet crookedly.

Sideways movements / Lateral movements

Comes from one flange being pushed to the side for the other, and can e.g. a. come from mechanical stresses.

Twisting / Torsional movements

Comes from one flange being turned clockwise or counter-clockwise.

Vibrations

Often comes from poor process control.

Rubber expansion joints

Rubber expansion joints are affordable and durable.

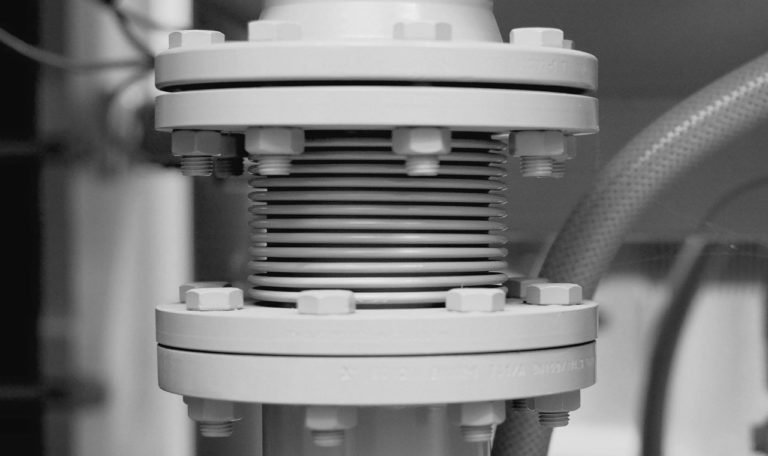

Metal expansion joints

Metal expansion joints are well suited where there are strong forces, especially lateral forces, where steel is needed to hold back the forces.

Fabric expansion joints

Fabric expansion joints, also sometimes called textile expansion joints, are suitable for large dimensions where rubber and steel becomes too heavy.

Do you not find what you are searching for?

Contact us and we will help you find ut!